In-Mold Decorations in Modern Production: A Comprehensive Guide

In-Mold Decorations in Modern Production: A Comprehensive Guide

Blog Article

Grasping In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Ideal Outcomes

In the realm of production, the art of in-mold decorations stands as an essential aspect of item layout and manufacturing. As sectors consistently seek innovative means to enhance aesthetic allure and performance, understanding the complexities of in-mold decorations has arised as a critical capability. From picking the appropriate materials to incorporating advanced style fads, the journey towards accomplishing optimum cause this domain name is multifaceted. By delving right into the approaches, trends, and finest techniques that underpin effective in-mold decoration processes, services can open a world of possibilities that not only raise the visual attraction of their items but also enhance production performance and bolster consumer interaction.

Product Choice

Product choice is a crucial facet of grasping in-mold decorations, as it straight influences the high quality and resilience of the final item. When choosing materials for in-mold decors, it is necessary to consider variables such as compatibility with the molding process, the preferred aesthetic result, and the ecological conditions the item will certainly face.

Furthermore, the chosen product ought to have excellent adhesion properties to make sure that the decor adheres securely to the substratum throughout the molding process. Bond in between the design and the product is crucial for stopping delamination and making certain long-lasting visual charm. In addition, materials with high heat resistance are liked for in-mold decors, specifically for products that will be exposed to elevated temperature levels throughout their lifecycle. By meticulously selecting the suitable material for in-mold designs, makers can boost the total top quality and resilience of their products, satisfying the expectations of both clients and end-users.

Style Advancement

A necessary consider advancing the field of in-mold decorations is the continual expedition and application of style development techniques. Layout advancement plays a vital function in enhancing the aesthetic allure, performance, and overall quality of items produced using in-mold decor processes. By incorporating cutting-edge style elements, manufacturers can separate their products in the market, bring in consumers, and remain in advance of competitors.

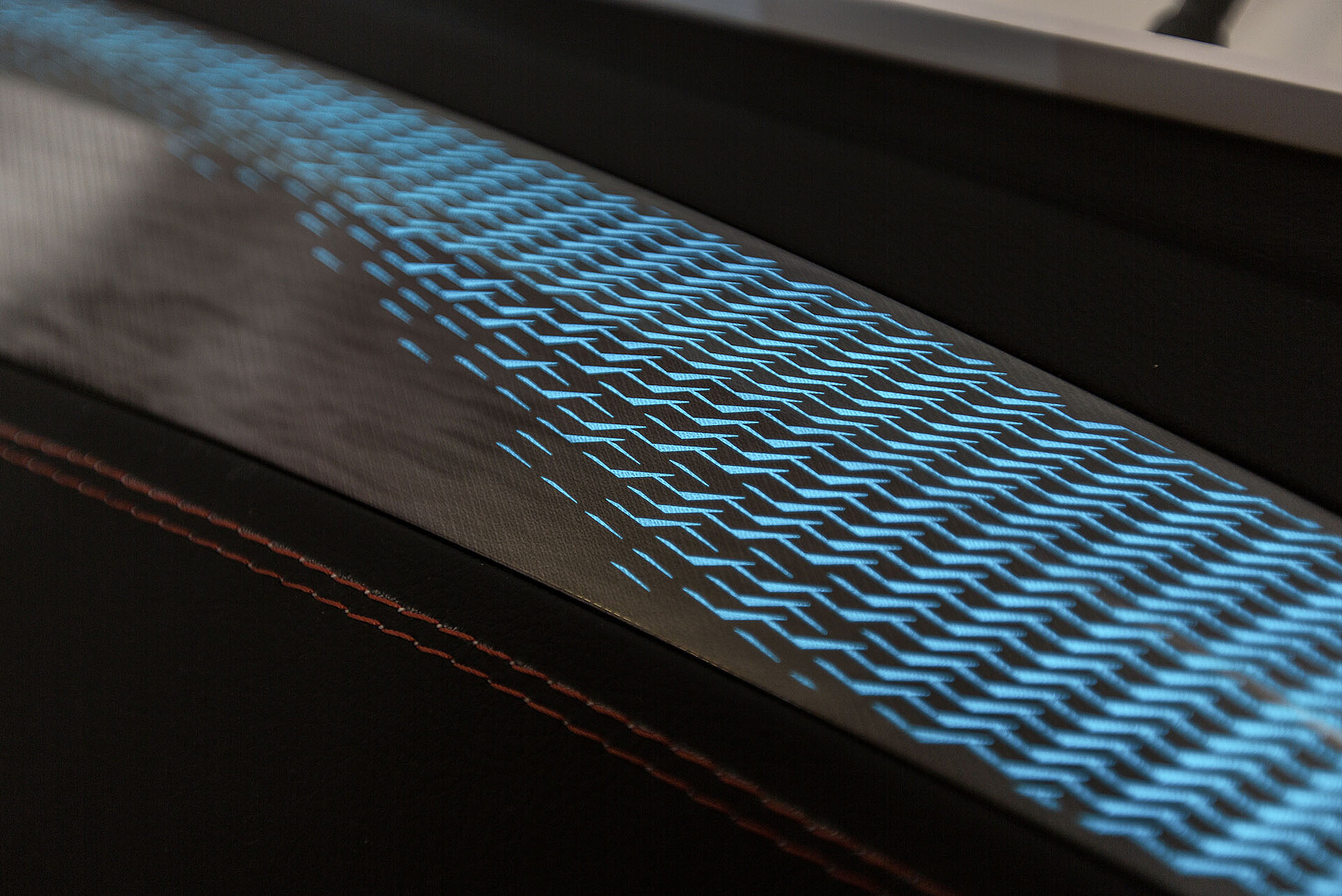

Among the essential aspects of style advancement in in-mold decors is the combination of intricate patterns, appearances, and graphics that were previously testing to accomplish with traditional decor methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to develop complex and thorough styles that can be seamlessly transferred onto shaped parts. In addition, the use of vivid colors, metal coatings, and special results like gloss or matte textures can additionally elevate the visual allure of in-mold decorated products.

In addition, design advancement extends beyond aesthetics to include useful enhancements such as ergonomic shapes, incorporated features, and customizable aspects that satisfy particular individual demands. By embracing style advancement, suppliers can unlock new opportunities for creative thinking, personalization, and product distinction in the affordable landscape of in-mold decors.

Manufacturing Efficiency

Efficient production processes are necessary for converting the cutting-edge designs established in the area of in-mold designs right into high-grade ended up items that fulfill market needs and customer assumptions. In the world of in-mold designs, production effectiveness includes different essential aspects that contribute to the overall visit site success of the manufacturing procedure. One crucial component is the optimization of mold and mildew layout and tooling to make certain specific and smooth design transfer onto the end product. By fine-tuning mold and mildew setups and investing in top quality tooling materials, manufacturers can boost performance and consistency in production.

Automation not only speeds up the manufacturing procedure yet additionally boosts precision and repeatability, leading to a more uniform and premium end item. i thought about this In general, an alternative technique to manufacturing effectiveness is vital in maximizing the potential of in-mold decoration techniques and achieving optimal outcomes in the affordable market landscape.

Quality Assurance Actions

What are the key approaches for guaranteeing stringent high quality control measures in the world of in-mold decorations? Quality control procedures are paramount in in-mold decor procedures to guarantee the production of top quality and remarkable ended up items.

Making use of advanced modern technologies such as automated assessment systems can also improve the quality assurance procedure by offering trusted and accurate data for evaluation. These systems can spot flaws that might be missed by hands-on examinations, thereby enhancing total item quality and consistency.

Routine training and growth programs for employees involved in the in-mold design procedure can additionally contribute to preserving top notch criteria. By educating staff on finest techniques, top quality assumptions, and the importance of interest to detail, business can cultivate a society of top quality awareness throughout the organization.

Consumer Appeal

To enhance the bankability of in-mold design products, providing and comprehending to consumer choices play an important role in establishing their charm and success. Supplying personalization options such as tailored styles, shade variations, and textural elements can substantially enhance the allure of in-mold decoration items.

Conclusion

In-mold decorations supply a functional and effective way to boost item looks. Grasping in-mold decorations requires an all natural technique that thinks about all aspects of the production procedure to guarantee success.

In the realm of production, the art of in-mold designs stands as a pivotal facet of product design and manufacturing. Layout technology plays a vital role in enhancing the visual appeal, capability, and general quality of items manufactured making use of in-mold directory design processes.One of the crucial aspects of layout development in in-mold decors is the combination of intricate patterns, appearances, and graphics that were previously testing to achieve with standard decoration techniques.Efficient manufacturing procedures are vital for translating the ingenious designs developed in the area of in-mold decorations into high-quality completed items that meet market needs and customer expectations. Using customization choices such as tailored designs, shade variants, and textural elements can substantially boost the appeal of in-mold design items.

Report this page